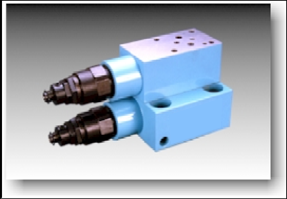

The Covers CVC*2RS are designed to hold Hydronine make 2 port slip-in cartridge valves model CV*** in the cavities machined as per ISO 7368, and are meant to provide duel pressure Pilot operated Relief function, using combination of a Slip-in Cartridge having a poppet ratio of 1:1, and two Relief valves, selectable by means of energizing a solenoid valve mounted on it

Please note that difference in the pressure setting between the 1st Relief valve and the 2nd Relief valve (as marked in the circuits below) must be minimum 10 bar; 2nd Relief valve being set at lesser pressure of the two.

By using a Double solenoid valve as shown in the circuit, an additional unloading function can also be achieved by the cover.

The Covers H9-LC*DE are designed to hold Hydronine make 2 port slip-in cartridge valves model H9-LC*** in the cavities machined as per ISO 7368, and control opening and closing of the cartridge valve by electrical signal

Uses Solenoid operated directional control valve having interface confirming to ISO 4401-03-02 for actuation.

Normally used for directional control function of the cartridge.

Configurations available are as shown in the hydraulic symbols below.

The Covers CVC*R are designed to hold HYDRONINE make 2 port slip-in cartridge valves model CV*** in the cavities machined as per ISO 7368, and are meant to create a pilot operated relief function, when combined with a valve having a poppet area ratio of 1:1.

The covers have options of having pressure adjustment facility by means of Set screw or a Hand knob.Clockwise rotation of the screw increases the pressure setting.

These covers are also available with an optional facility to mount on them, a Solenoid operated Directional Control Valve to give the combination an added feature of unloading a pump or regulating pressure and exhausting a cylinder side by means of an electrical signal to the Solenoid.

The Covers with Stroke limiter model H9-LC*STS* are designed to hold Hydronine make Cartridge valves in cavities machined as per ISO 7368, and control opening and closing of the cartridge valve by electrical signal. Effective closing pressure is the pressure from either port 'X' or 'Z1', which ever is higher.

Cover has built-in seat type shuttle valve to select pressure for closure of the cartridge.

The flow passing through the cartridge can be controlled by controlling the opening of the poppet by means of a Stroke limiter screw provided in the cover. The throttling is effective in either directions. Clockwise rotation of the Stroke Throttle screw will decrease the flow passage, thereby decreasing the flow.

The Covers with Stroke limiter model CVC*TS* are designed to hold Hydronine make Cartridge valves model CV*** in cavities machined as per ISO 7368 , and provide facility to control the oil flow passing through these cartridges by electrical signal.

Cover has built-in seat type shuttle valve to select pressure for closure of the cartridge.

The flow passing through the cartridge is controlled by controlling the opening of the poppet by means of a Stroke limiter screw provided in the cover . The throttling is effective in either directions.

Clockwise rotation of the Stroke Throttle screw will decrease the flow passage , thereby decreasing the flow.

A check nut is provided to lock the Throttle Screw in its position.

A soft rubber cap prevents accidental damage to the Throttling Screw .

These Stroke limiters are more effective with cartridges having poppet with cushion nose.

The Covers H9-LC*S are designed to hold Hydronine make 2 port slip-in cartridge valves in the cavities machined as per ISO 7368 . It also meant to connect port C of the Cartridge to one of the two pressure sources, brought to its port X and port Z1 . Automatic selection of higher source pressure and isolation of these pressures from one another is done by the built in Shuttle valve in the cover.

Application of pressures at port C isolates port A of the cartridge from its port B.

To open the passage in the cartridge, it is essential to depresssuize both the input sources provide to the cover.

The resultant pressure source acting on the port C is also available at port Z2 provided on the cover.

The Covers H9-LC*SDE are designed to hold Hydronine make 2 port slip-in cartridge valves in the cavities machined as per ISO 7368, with built in facility to control the operation of the cartridge valve as under,

Refering to the circuits shown below, the built-in Shuttle valve in the cover selects higher of the pilot pressures brought to the cover at its ports X and Z1 and admits it to the port P of the Directional Control Valve mounted on the cover.

In case of use of cover model H9-LC*SDEA, in de-energized condition of the Sol. Directional control valve mounted on the cover, the port A, which is normally connected to port P through the valve , gets directly connected to the control port C on the cartridge interface, thereby keeping the cartridge valve normally closed . Upon energizing the Solenoid, the control port C gets connected to tank via the Directional Control Valve and therefore the cartridge passage opens. In this configuration of the cover, port B of the Solenoid operated Directional Control Valve is available at port Z2 on the cover for actuation of other cartridge/s.

In case of use of cover model H9-LC*SDEB, in de-energized condition of the Sol. Directional control valve mounted on the cover , the port B , which is normally connected to port T through the valve, gets directly connected to the control port C on the cartridge interface, thereby keeping the cartridge valve normally opened. Upon energizing the Solenoid, the control port C gets connected to pressure via the Directional Control Valve and therefore the cartridge passage closes. In this configuration of the cover, port A of the Solenoid operated Directional Control Valve is available at port Z2 on the cover for actuation of other cartridge/s.

The Covers H9-LC*SDEAA and H9-LC*SDEAB are designed to hold Hydronine make 2 port slip-in cartridge valves in the cavities machined as per ISO 7368, with built in facility to control the operation of the cartridge valve as under,

Referring to the circuits shown below, the built-in Shuttle valve in the cover selects higher of the pilot pressures brought to the cover at its ports X and from either A (in case of cover model H9-LC*SDEAA) or B (in case of cover model H9-LC*SDEAB) to the control port C of the cartridge valve.

Thus, these configurations are very convenient in cartridge circuits when one wishes to use a Cartridge valve as a solenoid controlled leakage-free gate (leakage-free in the direction of the cartridge from port B to port A). This can be achieved by connecting control port X to port B of the cartridge in manifold.

If done so, by using the cover model H9-LC*SDEAA, with solenoid in de-energized condition, one can achieve a function of free flow with check from its port A to port B. By energizing the solenoid, the passage in the cartridge (from port A to B or B to A) can be blocked.

By using the cover model H9-LC*SDEAB, with solenoid de-energizes condition, one can block the passage in the cartridge (from port A to B or B to A). By energizing the solenoid, free flow with check from its port A to port B can be achieved.

The Covers with Stroke limiter model H9LC*TSX are designed to hold Hydronine make Cartridge valves in cavities machined as per ISO 7368, and provide facility to control the oil flow passing through these cartridges.

The flow passing through the cartridge can be controlled by controlling the opening of the poppet by means of a Stroke limiter screw provided in the cover. The throttling is effective in either directions.

Clockwise rotation of the Stroke Throttle screw will decrease the flow passage, thereby decreasing the flow.

A check nut is provided to lock the Throttle Screw in its position.

A soft rubber cap prevents accidental damage to the Throttling Screw .

These Stroke limiters are more effective with cartridges having poppet with cushion nose.

The covers H9-LC*X are designed to hold Hydronine make Cartridge valves in cavities machined as per ISO 7368, and to provide oil passage to their control port C via X port provided on the cover to control the opening and closing operation of the cartridge valve.

The passage has an orifice screwed into it, for influencing the rate of opening and closing of the poppet of the cartridge valve, there by reducing / eliminating shocks in the main circuit oil flow. The threaded port on the cover can also be used for diagnostic purpose or for parallel supply of oil to some other function. This is particularly useful for the onsite modifications to the circuit.